Page 1 - SETeMa_Flyer_UKv160218

P. 1

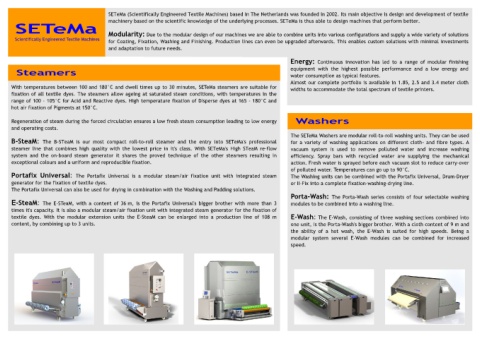

SETeMa (Scientifically Engineered Textile Machines) based in The Netherlands was founded in 2002. Its main objective is design and development of textile

machinery based on the scientific knowledge of the underlying processes. SETeMa is thus able to design machines that perform better.

SETeMa

Scientifically Engineered Textile Machines Modularity: Due to the modular design of our machines we are able to combine units into various configurations and supply a wide variety of solutions

for Coating, Fixation, Washing and Finishing. Production lines can even be upgraded afterwards. This enables custom solutions with minimal investments

and adaptation to future needs.

Energy: Continuous innovation has led to a range of modular finishing

Steamers equipment with the highest possible performance and a low energy and

water consumption as typical features.

Almost our complete portfolio is available in 1.85, 2.5 and 3.4 meter cloth

With temperatures between 100 and 180°C and dwell times up to 30 minutes, SETeMa steamers are suitable for widths to accommodate the total spectrum of textile printers.

fixation of all textile dyes. The steamers allow ageing at saturated steam conditions, with temperatures in the

range of 100 - 105°C for Acid and Reactive dyes. High temperature fixation of Disperse dyes at 165 - 180°C and

hot air fixation of Pigments at 150°C.

Regeneration of steam during the forced circulation ensures a low fresh steam consumption leading to low energy Washers

and operating costs.

The SETeMa Washers are modular roll-to-roll washing units. They can be used

B-SteaM: The B-STeaM is our most compact roll-to-roll steamer and the entry into SETeMa's professional for a variety of washing applications on different cloth- and fibre types. A

steamer line that combines high quality with the lowest price in it's class. With SETeMa's High STeaM re-flow vacuum system is used to remove polluted water and increase washing

system and the on-board steam generator it shares the proved technique of the other steamers resulting in efficiency. Spray bars with recycled water are supplying the mechanical

exceptional colours and a uniform and reproducible fixation. action. Fresh water is sprayed before each vacuum slot to reduce carry-over

of polluted water. Temperatures can go up to 90°C.

Portafix Universal: The Portafix Universal is a modular steam/air fixation unit with integrated steam The Washing units can be combined with the Portafix Universal, Drum-Dryer

generator for the fixation of textile dyes. or II-Fix into a complete fixation-washing-drying line.

The Portafix Universal can also be used for drying in combination with the Washing and Padding solutions.

Porta-Wash: The Porta-Wash series consists of four selectable washing

EE E E-SteaM: The E-STeaM, with a content of 36 m, is the Portafix Universal's bigger brother with more than 3 modules to be combined into a washing line.

times it's capacity. It is also a modular steam/air fixation unit with integrated steam generator for the fixation of

textile dyes. With the modular extension units the E–SteaM can be enlarged into a production line of 108 m E-Wash: The E-Wash, consisting of three washing sections combined into

content, by combining up to 3 units. one unit, is the Porta-Wash's bigger brother. With a cloth content of 9 m and

the ability of a hot wash, the E-Wash is suited for high speeds. Being a

modular system several E-Wash modules can be combined for increased

speed.